In those days when we lived in the first days of 2020, when we look at the previous 10 years, the concept of Industry 4.0 was not even present. This even reveals how important 10 years has been in the manufacturing industry. So how will production change in 2020 and the next 10 years, what will be the determining factors, let’s look at it together.

In those days when we lived in the first days of 2020, when we look at the previous 10 years, the concept of Industry 4.0 was not even present. This even reveals how important 10 years has been in the manufacturing industry. So how will production change in 2020 and the next 10 years, what will be the determining factors, let’s look at it together.

1-Industrial Wearable Technology Not Too Far

From field service to installation, one of the most effective technologies of the next decade will be wearable technologies. It is no longer futuristic to follow the temperature of a panel with your glasses or to understand the defective equipment with a holo lens at a glance. For example, you have encountered a major malfunction in the field and want to send it to your supervisors immediately. If we say that it will be possible to record the video of the fault and send an e-mail with Google Glass, I think it will be enough to understand the change brought by this technology.

2-Business Models are Changing The B2B Is Leaving Its Place To B2BC

Many manufacturers that traditionally have a B2B business model are switching to a B2B2C (business-to-consumer) model due to the many benefits of selling directly to consumers. Okay but why?

Increased Profit: You can set your products for the consumer instead of wholesale prices.

Faster Time to Market: You no longer have to deal with B2B companies’ long purchase cycles or test and prototype processes. You can launch your product directly to the market.

Brand Control: You are the owner of your brand. It will not be used or misrepresented by third parties.

Price Control: You can get stronger in the market with your own competitive price.

Better Customer Data: Selling directly to customers, collecting better insights about them, collecting data that results in stronger relationships and increased sales. It does not seem possible to catch them in B2B sales.

3-Cyber Security Will Be One Of The Most Important Subjects

As smarter, more communicative products and production lines become widespread, the cyber deficits of these systems increase. The challenge is the lack of a ready-made industrial cyber security system. Cyber security is a process that progresses by gradually making it ready for use. Many people in a factory, from the production manager to the assembly operator are responsible for cyber security. Therefore, cyber security requires serious cooperation and awareness among employees. Today, automotive production (39.3 percent) and building automation systems (37.8 percent) rank first in terms of the ratio of industrial computers targeted by harmful objects.

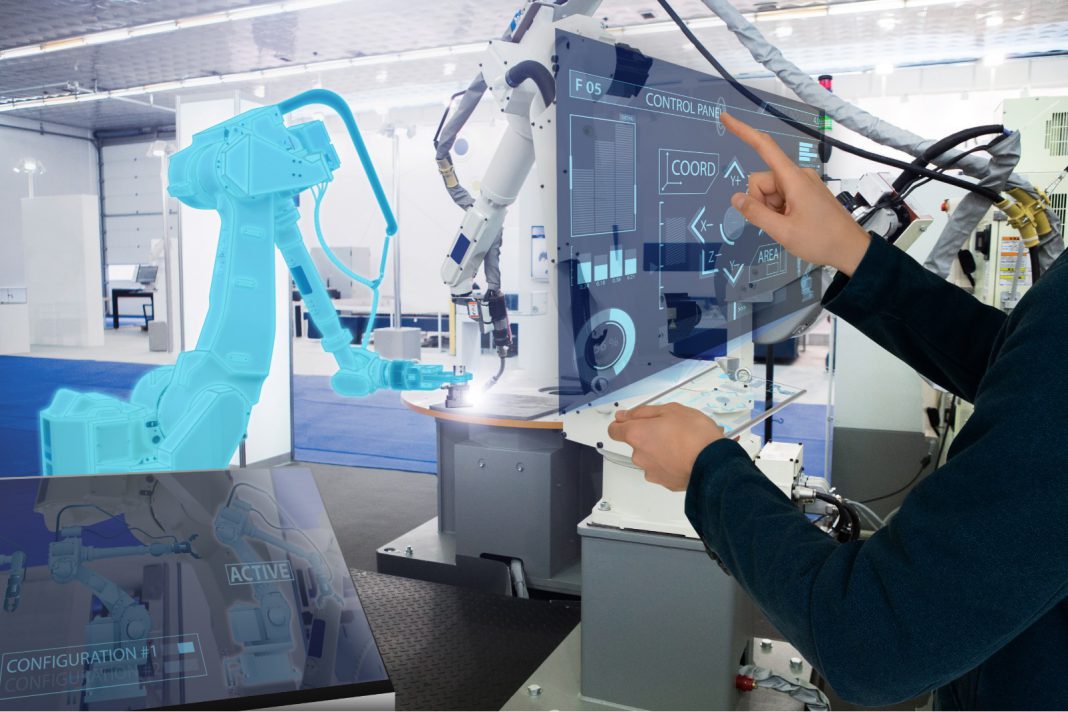

4-Augmented Reality: The Easiest Way to New Productivity